1 Appearance requirements and structural analysis of door handles

Figure 1 shows a door handle of a new energy vehicle. Material is polycarbonate / acrylonitrile-butadiene-styrene plastic (PC/ABS) with a shrinkage rate of 0.5%. Material has good impact resistance. It has high hardness and strength and good dimensional stability. The overall dimensions of product are 190 mm * 141 mm * 107 mm, average thickness is 2.5 mm, and volume is 60.5 cm 3 . Outer surface of product must be high-gloss, and no gate marks, air marks, flash, weld marks or shrinkage dents are allowed. Outer contour space of product is complex in shape, with as many as 10 undercuts in inner structure, and multiple reinforcement ribs at both ends, which makes demoulding and exhaust difficult, increases difficulty of mold design.

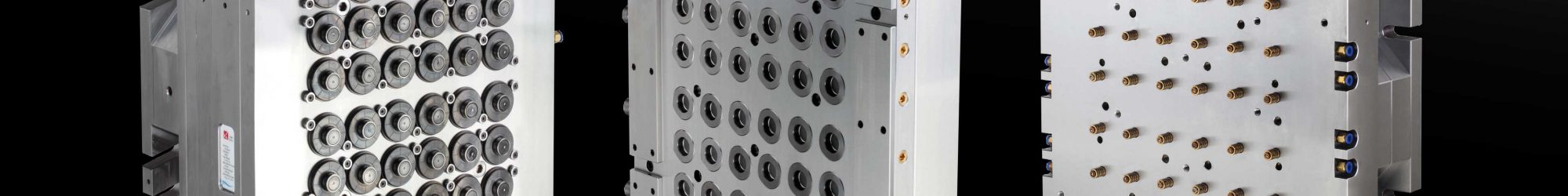

2 Hot runner gating system design and CAE analysis

2.1 Design of hot runner pouring system

Design of pouring system in mold is particularly critical. For small-sized molded products with a single gate, gate position is generally prioritized at the center of product to be molded, which will affect subsequent layout of demoulding mechanism, opening of exhaust slot, etc. Product material is PC/ABS, which has poor fluidity and has high requirements on outer surface of product. Therefore, design principles of runner gating system are as follows: ① Make material melt quickly fill mold cavity and reduce loss of pressure and heat; ② It cannot affects outer surface of product, that is, gate marks cannot be left on appearance surface. Therefore, a side gate is used, which is located on inner surface of edge of product. Gate size is 10 mm * 1.2 mm, and depth is smaller than wall thickness of edge of product. A system that combines hot runner and ordinary runner uses a φ12 mm valve-type hot runner, and ordinary runner uses a 10 mm*8 mm U-shaped runner, as shown in Figure 2.

2.2 CAE analysis

Mold adopts a 2-cavity hot runner gating system, and a double-level mesh type is used in Moldflow. Mesh is processed and repaired using mesh tools to obtain a finite element model that meets requirements, as shown in Figure 3. Material selection grade is MAC-701, set pouring position, and input process parameters such as mold temperature 60 ℃, melt temperature 245 ℃, cooling time 30 s, etc. into Moldflow software, set the rest to automatic. Final analysis results are shown in Figures 4 to 6. Time for melt to fill cavity is 1.26 s, maximum injection pressure is 16.63 MPa, there are air pockets in undercuts and ribs of product, and there is no underfilling of cavity.

3 Door handle injection mold structure design

3.1 Product parting surface and molded parts design

In order to ensure smooth demoulding of molded products and realize automated production, edge of the largest appearance outline of product is generally selected as parting surface. Since middle part of door handle is A surface with a rounded corner transition, parting surface of this feature is extended by 12 mm in demoulding direction. Final parting surface design is shown in Figure 7. Mold core is shown in Figure 8 and adopts an integral structure to reduce mold size and manufacturing costs. Since PC materials release corrosive gases during high-temperature molding, core material is made of S136 mold steel, which has good corrosion resistance, wear resistance and good polishability. Hardness can reach 50 HRC after heat treatment.

3.2 Design of side core pulling and pushing mechanism

Since material is fed from opposite side of product to be formed and material hardness is high, a forced demoulding mechanism cannot be used. The mold adopts an inverted structure, that is, core and ejection system are set in fixed mold, cavity is set in movable mold, double slider core-pulling mechanism of fixed mold is shown in Figure 9. Outer surface of product uses two fixed mold large slide blocks to complete side core pulling. Core pulling distance on the side without gate is 24 mm, which is shorter. Inclined guide pillar core pulling mechanism can be used because width of slider 8 reaches 185 mm. In order to ensure stability of slider during operation, two φ25 mm inclined guide posts 7 are designed with an inclination angle of 15°. Effective working length of inclined guide posts is calculated to be 136 mm, which is fixed on cavity plate side of movable mold through screws. At the same time, two springs with an outer diameter of φ20 mm are added to the bottom of slider to increase lateral core pulling force. A guide slider 6 is designed in the middle of slider to improve movement accuracy of slider. H8/f8 clearance fit is used for sliding guide, roughness of mating surface is Ra≤0.8 μm, guide strip is generally made of a combination of graphite and brass to improve wear resistance. There is a gate and a common runner on the other side of molded product, and core-pulling distance is 75 mm. If inclined guide pillar mechanism is used, the overall size of mold will be increased and manufacturing cost will be increased. Therefore, a hydraulic cylinder core-pulling mechanism is used. Just add parts to fix hydraulic cylinder 4 in this area. At the same time, there is a limit rod 3 on slider 5. By contacting the two travel switches 1 and 2 fixed on mold, it can be judged whether slider is working in place to ensure smooth operation of mold; at the same time, corresponding exhaust grooves are designed on molding surfaces of two sliders to prevent trapped air. Material of molded sliders is NAK80 pre-hardened plastic mold steel, which is uniform in material and has good polishing performance.

1. Limit switch 2. Limit switch 3. Limit rod 4. Hydraulic cylinder 5. Slider 6. Guide slide 7. Inclined guide post 8. Slider

Since there are 10 undercuts on the back of product, demoulding direction of each undercut is different. According to actual demoulding angle, a corresponding square oblique push slide combination mechanism is designed. All oblique push rods use a brass guide plate to enhance stability of push-out and reset to prevent slipping, and φ8 mm push rods are installed at positions with deeper reinforcements, as shown in Figure 10.

3.3 Cooling system design

In order to shorten molding cycle of product in actual production process, rationality of design of mold cooling water path is crucial. It is generally placed as close to product as possible to facilitate heat exchange. Since product is in direct contact with core and slider on fixed mold side, two independent cooling circuits of φ11 mm are designed on core side, and a water-isolating sheet structure is adopted; due to limited space of slider, an independent water channel with a diameter of 8 mm is designed at each slider. The overall structure of cooling system is shown in Figure 11, including surrounding parts of work-in-process. Through Moldflow cooling analysis, warpage deformation results of product with cooling circuit are shown in Figure 12. Maximum deformation is 0.784 mm, which meets technical requirements.

4 Mold structure and working principle

Mold structure is shown in Figure 13. It adopts a flip-chip structure, with ejection system and core set in fixed mold, and cavity plate set in movable mold, which is opposite to traditional mold structure. Mold adopts a hydraulically controlled valve-type hot runner system with an overall size of 1 000 mm * 760 mm * 800 mm. Cavity plate and core adopt an integral structure, other mold plates and parts can be customized through standard mold bases to shorten mold manufacturing cycle.

1. Moving mold base plate 2. Pad 3. Moving mold plate 4. Push rod 5. Adjustment block 6. Push out hydraulic cylinder 7. Reset rod 8. Limit switch 9. Push rod fixed plate 10. Push plate 11. Backing plate 12. Reset travel switch 13. Fixed mold base plate 14. Positioning ring 15. Hot gate sleeve 16. Valve needle hydraulic cylinder 17. Hot runner heating plate 18. Hot runner fixed plate 19. Slide seat 20. Guide column 21. Guide sleeve 22. Heating interface 23. Slider bead 24. Limiting block 25 Slider guide strip 26. Fixed mold slide 27. Hydraulic joint 28. Hydraulic joint 29. Hydraulic cylinder 30. Slider 31. Limiting rod 32. Limit switch 33. Travel switch 34. Pressure-bearing plate 35. Inclined guide column 36. Waterway joint

Mold working principle: After mold is closed, connect all water pipe joints to mold temperature machine, then connect hot runner control box to interface 22; set corresponding temperature, and after injection molding machine is heated, PC/ABS plastic melt is plasticized under action of screw in barrel. After screw is plasticized to set position, hydraulic system of injection molding machine is converted to injection pressure, melt is injected into mold sprue sleeve and enters mold cavity through runner. After melt fills cavity, it enters pressure-holding and feeding stage, then cooling water enters mold cooling waterway through mold temperature controller to accelerate cooling of molded product; after cooling is completed, movable mold of mold begins to move under action of injection molding machine. Inclined guide column 35 drives fixed mold slide block 26 to complete core pulling movement, drives slide block 30 to move sideways under action of hydraulic cylinder 29. When limit rod 31 connected to slider 30 hits limit switch 32, mold completes lateral splitting. At this time, push-out hydraulic cylinder 6 begins to flow in hydraulic oil. Under action of two push-out hydraulic cylinders, push plate 10 drives inclined push assembly through slide 19 to push out product. When push-out hydraulic cylinder 6 hits limit switch 8, movement is stopped to complete demolding; then hydraulic cylinder 6 is pushed out to reset, when it touches reset stroke switch 12, push plate completes reset, and then hydraulic cylinder 29 drives slider 30 to reset. When limit rod 31 touches stroke switch 33, slider is reset, and finally movable mold is closed under action of injection molding machine to complete a cycle of injection.